Categories

Tags

-

#fiber laser cutting machines

#laser cutter

##lasercuttingmachine

#CNC Granquartz

#3 In 1 Laser Cleaning Machine

#Plasma Cutting Table

#Laser Cleaning Machine

#CNC Wood Laser Cutting Machine

#laser paint removal machine

#CNC Router Factory

#3 In 1 Laser Welding

#Fiber Laser Welding Machine

#ATC CNC Router

#Cleaning Machine for Wood

#laser cut wood

#Plasma Cutter

#CNC PLASMA CUTTER

#Fiber Laser Welding Gun

#Laser Rust Removal Gun

#Metal Sheet Plate Laser Cutting Machine

#CO2 Laser Cutting and Engraving Machine

#Fabric Cutting Machine

#CNC Machines for Woodworking

#Furniture Making Machine

#Edge Banding Machine

#Rust Removal

#Digital Cutting Machine

#3D CNC Router

#Stone Bridge Cutting Machine

Archives

3 In 1 Laser Welding Cutting Cleaning Machine

-

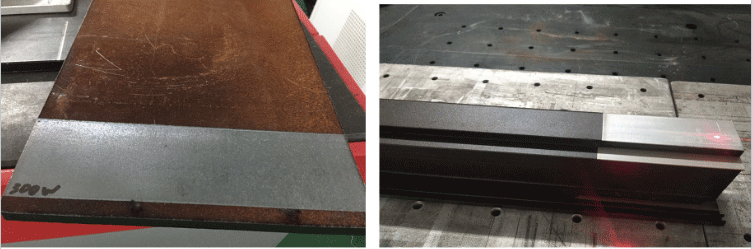

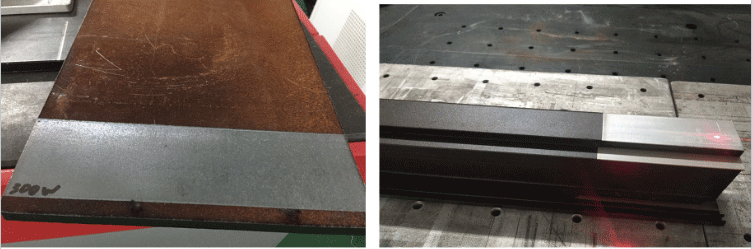

A 3 in 1 laser welding cutting cleaning machine is a device that combines three laser processes: welding, cutting, and cleaning. This type of machine is designed to offer a wide range of capabilities and can perform multiple functions using different laser heads or nozzles.

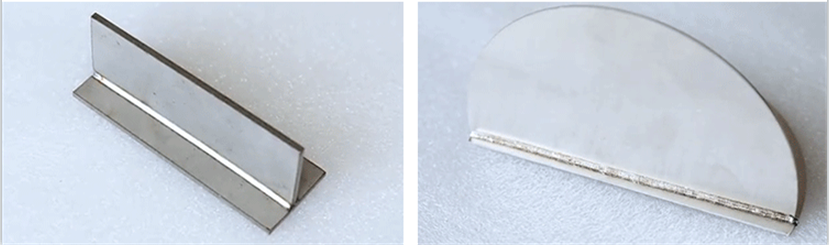

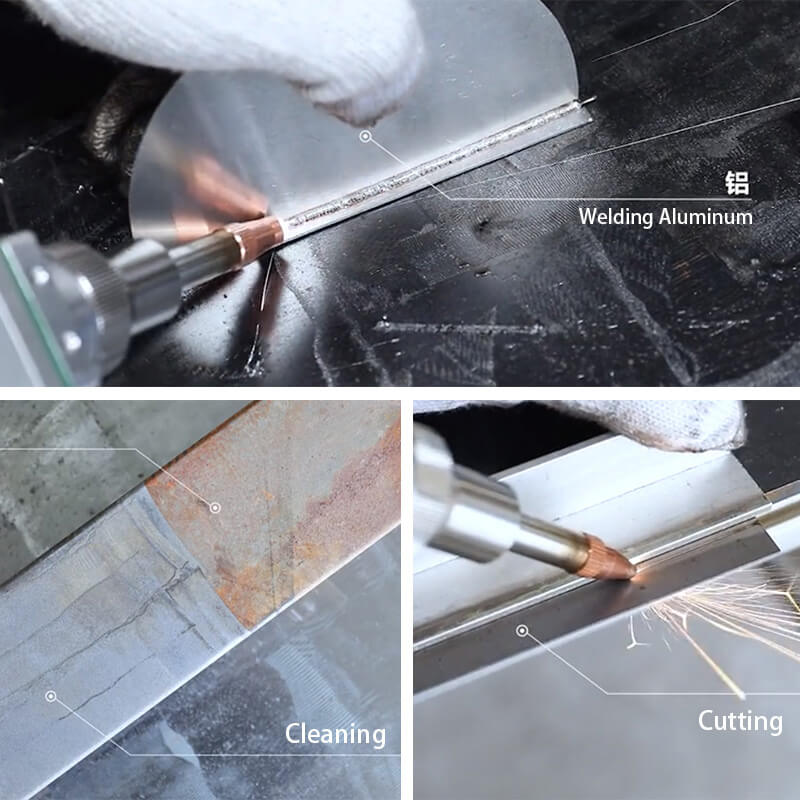

Laser welding involves using a high-powered laser beam to fuse two pieces of material together. This process is precise and produces a high-quality weld with minimal heat input, resulting in less distortion and less material damage.

Laser cutting, on the other hand, involves using a laser beam to cut through materials such as metal, plastic, and wood. This process is highly accurate and can produce intricate cuts and shapes with ease.

Laser cleaning, as previously mentioned, involves using a laser beam to remove rust, paint, and other contaminants from a surface. This process is non-abrasive and can clean even the most delicate surfaces without damaging them.

Combining these three processes in one machine offers several benefits:

- Versatility: A 3 in 1 laser welding cutting cleaning machine offers a wide range of capabilities, allowing users to switch between different processes as needed.

- Time and cost savings: Because multiple processes can be performed using a single machine, users can save time and money by not having to purchase and maintain separate machines for each process.

- High precision: Laser technology allows for precise control over the welding, cutting, and cleaning processes, resulting in high-quality results.

- Reduced waste: Laser technology produces less waste than traditional methods, making it an eco-friendly solution.

Overall, a 3 in 1 laser welding cutting cleaning machine is a powerful tool for many industries, including manufacturing, automotive, and construction, where high precision, efficiency, and versatility are essential.

The features of a 3 in 1 laser cleaning machine or a 3 in 1 laser welding cutting cleaning machine may vary depending on the specific model and manufacturer. However, some common features that these machines may have include:

- Multiple functions: As the name suggests, these machines offer three functions in one device, which can be used for cleaning, welding, and cutting. This makes them versatile and convenient for a wide range of applications.

- Laser source: The machines are equipped with high-powered laser sources that can generate high-energy laser beams to perform the cleaning, welding, and cutting tasks with precision and accuracy.

- Control systems: The machines are typically equipped with computerized control systems that allow users to adjust and monitor the laser beam’s power, speed, and focus to ensure the desired results.

- Safety features: Laser machines can be hazardous to operate, and as such, they are typically equipped with various safety features, such as interlocks, shields, and emergency stop buttons to protect the user and the environment.

- Easy to use: Many models of these machines are designed to be user-friendly and straightforward to operate, with intuitive interfaces and straightforward controls.

- Maintenance and durability: These machines are built with high-quality materials and components and are designed for heavy-duty use. They often require minimal maintenance and are built to last, providing long-term reliability and performance.

Overall, the features of a 3 in 1 laser cleaning machine or a 3 in 1 laser welding cutting cleaning machine are geared towards providing users with a highly effective, efficient, and versatile tool that can deliver high-quality results.

A 3 in 1 laser welding cutting cleaning machine is a versatile tool that finds applications in a variety of industries, including:

- Automotive: The machine can be used in the automotive industry to clean, weld, and cut parts such as engine blocks, transmissions, and exhaust systems.

- Aerospace: The machine can be used in the aerospace industry to clean, weld, and cut aircraft parts such as turbine blades, fuel nozzles, and structural components.

- Manufacturing: The machine can be used in the manufacturing industry to weld, cut, and clean various parts and components, including sheet metal, pipes, and machinery parts.

- Construction: The machine can be used in the construction industry to weld, cut, and clean materials such as steel beams, concrete, and brickwork.

- Electronics: The machine can be used in the electronics industry to weld, cut, and clean components such as circuit boards, sensors, and connectors.

- Medical: The machine can be used in the medical industry to clean, weld, and cut surgical tools, medical devices, and implants.

- Jewelry: The machine can be used in the jewelry industry to weld and cut precious metals such as gold, silver, and platinum.

Overall, the 3 in 1 laser welding cutting cleaning machine is a versatile tool that can find applications in various industries, where precision, efficiency, and versatility are essential.

3 In 1 Laser Cleaning Machine: at Good Price & Cost-effective

3 in 1 multi-function 1000w 1500w 2kw 3kw handheld fiber laser welding cutting cleaning machine steel laser welder,different size and different function nozzle for free(welding and cutting),wire feeder: touch screen control, support various welding wires with diameters of 0.8/1.0/1.2/1.6/2.0mm. It will be best choice for customers, because the system can do laser welding, cleaning (rust removal), handheld metal cutting in one machine. The laser power have 1000w, 1500w, 2000w & 3000w for optional.

3 in 1 Laser Cleaning Machine Features

3 in 1 Laser Cleaning Machine FeaturesOne machine, bringing together three functions: welding, cleaning and cutting, the conversion of each function is convenient and simple.

High-efficiency cleaning, saving time, without grinding and non-contact. The handheld cleaning head has a simple handheld structure and is easy to carry.

Equipped with a touch screen, it is convenient to switch parameters during work and simplify the operation. Weight 0.8kg, light to use without fatigue.

Built-in high efficiency chiller, the whole machine has a compact structure and weighs only 160KG after packing with auto wire feeder.

It is easy to solve the environmental pollution problems caused by chemical cleaning without using any chemicals and cleaning liquids.

3 in 1 laser welder

The 3-in-1 function laser welding machine is now very popular in the market. It is designed to integrate laser welding, easy laser cleaning, and manual laser cutting in one welding machine with the aim of saving costs for customers. If you have to buy three machines at the same time, the cost will become very high. But this 3-in-1 laser welding machine has its limitations, it is not so perfect and can’t replace laser cleaning machine and laser cutting machine completely。Laser welding function

It is a laser welding machine, so its core function is still the welding function.laser welding compares with other welding methods, such as electric welding, tig welding, gas welding, etc. its advantages are:

1. Laser welding is more safe, because laser is visible light will not produce uv radiation, will not harm the operator’s personal health. you only need to wear laser protective glasses and use simple protective gloves.

2. Laser welding is more automated, it welding speed than the traditional welding method is more than 2 times faster.and can be combined with automatic wire feeder, in the field of welding thin material speed advantage is very large.

3. The instantaneous energy of laser welding is very high, which can instantly melt high melting point materials, such as aluminum, brass and other metals are also very suitable for using laser to weld.

3 in 1 laser cutting machine

Manual cutting function we just need to adjust the parameters of the system, and change the nozzle of the machine to the cutting nozzle (number-5 cutting nozzle), then you can do manual cutting.you can use it to cut metal pipes, angle iron, t rack, and other metal profiles. itcan also be used to manually cut carbon steel sheets, stainless steel sheets,etc. it can be used as a simple alternative to a hacksaw.3 in 1 laser cleaning machine

After replacing a focus lens for cleaning and adjust the mode to cleaning mode in the system. then the laser welding machine can be transformed into a simple function laser cleaning machine.

Built-in craft library

For common materials and thicknesses, the system has its own process parameter library, which makes the tedious processing easier and the processing efficiency higher.

Find out more about fiber laser cutting machines and laser welding machines at https://www.igolden-cnc.com/product-category/laser-cleaner/

What is the laser welding cleaning cutting machine 3 in one ?

In fact, the laser welding cleaning and cutting machine is a handheld laser welding machine evolved into a 3-in-1 machine. The purpose of cleaning is achieved by changing the focusing mode by replacing the focusing lens of the laser welding head,The laser head remains unchanged, just disassemble the first half of the welding head,change welding focus lens to clean focus lens. The control system exchange clean mode via welding system touch panel. as shown in the picture, Switching between welding and cleaning systems.

3 in 1 Handheld Fiber Laser Welding Cleaning Cutting Machine Tips :

Usually standard length is 10m, if you have other needs, we support shortening or lengthening.

Auxiliary gas: nitrogen or argonIf the welding surface effect is required to be white and bright, nitrogen or argon is required. If there is no requirement for the welding surface, add compressed air freeze Dryer, air is ok.

About wire feederIt’s the machine standard configuration, we will send to you together with the whole machine.

Machine warranty 2 years, we have professional after sale group, 24 hour online.

APPLICATIONS

3 in 1 handheld laser machine can be used in manufacturing, automotive, shipbuilding, battery, aerospace, kitchenware.

Shelves, elevators, guardrails, distribution boxes, ovens, metal furniture, biomedical, powder metallurgy, jewelry.

Electronics, hardware, optical communication, sensors, auto parts, porcelain teeth, glasses, solar energy.

and precision parts manufacturing.