Categories

Tags

-

#air compressor

#Double Wire Fence

#Malleable Iron Pipe Fittings

#hollow brick machine

#Filter Press

#laminate wood flooring

#seamless steel pipe

#Current Transformer

#Eccentric Butterfly Valve

#Aluminum Casting

# Control Valve Market

#adult diapers

#four way pipe fitting

#block machine for sale in usa

#24 inch butterfly valve

#8 inch butterfly valve

#8 inch butterfly valve price

#black pipe y fitting

#China non woven fabric Supplier

#monitor wa fire

#underground gate valve

#China Sprocket supplier

#office table for 4 person

#Automatic Filter Presses

#door manufacturers in china

#China wholesale iron doors manufacturers

#1610 co2 Non-metallic laser cutting machine for wood

#China Adult diaper pants manufacturer

#glass office partition walls

#china pipe fitting

#filter press plate

#silicone heater hose

#CATERPILLAR Excavator Carrier Roller

#China wet wipes manufacturing machine

#China ceramic fiber blanket manufacturer

#pallet coil nails

#Newly Designed Wafer Butterfly Valves for Long Life-Period

#membrane switch supplier

#8 pump

#adult diaper websites

#L-muscone supplier price in China

#French Exterior Double Glass Wrought Iron Doors

#ECO Customized Colors Personalized Grocery Bag PP Nonwoven Flat Bag

#silicone tubing suppliers

#cubicle desk organizer

#Steel Bar Grating manufacturer

#HITACHI EX120 Excavator Undercarriage Part Carrier Roller

#Partition Workstation hot sale in China

#membrane switch panels

#Excavator Undercarriage Part Carrier Roller

#cnc wood carving machine

#China Baby diaper pants factory

#coat buttons metal supplier

#ceramic fire board

#China 11.2 inch 20 gauge fine wire staples

#heart shaped pin badges clasp

#reflective road studs supplier

#china office table prices

#180 Degrees Silicone Hose

#triple offset butterfly valve

#China best wet wipes for face manufacturer

#baby diaper online sale

#wall saw blade

#aluminum silicate ceramic

#vacuum formed shapes

#China fiber laser cleaning machine for sale

#beauty bag factories

#carrier roller suppliers

#China danfoss h1b suppliers

#the maker mini laser engraver

#black pipe fitting

#custom metal tags for clothing

#6 piece bedding set

#China L-muscone supplier price

#Fiber laser machine manufacturers

#plush bath towels,white wash cloths,white wash cloth,100 cotton towels,organic washcloths wholesale

#cozy blanket,woven blankets,Green Throw Blanket,purple velvet throw blanket

#gray bedding set,Halloween Bedding Set,cartoon bedding sets,Bohemian Bedding Set

#parker pv080 piston pump

#china rod ends manufacturer

#servo hydraulic testing machine

#best metal laser engraver

#rollers for track

#china car part manufacturers

#China brick machines

#plastic coated chicken wire

#China KOMATSU PC300-7 Excavator Undercarriage Part Carrier Roller

#traffic cone manufacturers

#China adult diaper manufacturer

#non rising stem resilient seated gate valve

#reslient seat gate valve

#HITACHI DX370 Excavator Undercarriage Part Sprocekt

#Nonwoven Tote Bag

#china Φ20 Rain Hose 0.15mm supplier

#Isobutylbenzene supplier

#china fire foam monitor manufacturer

#raised reflective pavement markers

#engine crane

#bi pipe fittings

#heavy piece of metal with tag

#excavator track rollers for sale

#fire ground monitor

#wipes packaging

#high speed adult diaper machine

#diaper machine manufacturers

#polytunnel greenhouse

#soy sauce

#90903 63014

#fire sprinkler fittings

#drill bit spanish

#China overhead bridge crane

#Jingjin filter press

#black industrial piping

#reflective studs

#diaper machine story

#galvanized tee fittings

#portable track press

#China Alkanes suppliers

#wall cutting blade

#ceramic tile cutter blade

#lug vs wafer butterfly valve

#GI Pipe fittings

#upper track rollers for sale

#cnc leather

#flash point of oil

#generator radiator

#vibration knife cutting systems

#electric hoist

#floor jack

#bspt vs npt

#palet jack

#diaper procedure

#auto transmission temperature sensor

#field fence for goats

#concrete core bits

#manual chain hoist

#open cup flash point

#erw pipe

#waist bag outdoor

#marble cutting blade

#wholesale music instruments

#fiberglass cutting machine

#fire sprinkler control valve

#concrete cutting blade

#drum sets

#nappy making machine

#track tensioner assembly

#brushless motor drawing

#bulldozer track

#cellular health supplement

#fire sprinkler check valve

#Miniature Bed

#oliver valves

#sling

#Manual Fire Water Monitor

Archives

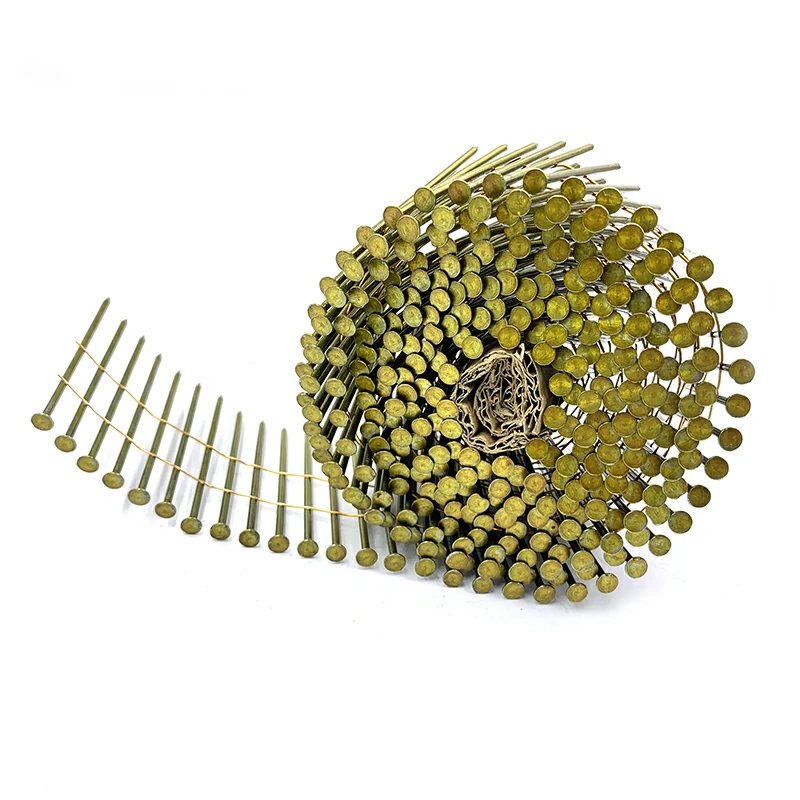

How do I choose the right point type for my pallet coil nails?

-

The point type of pallet coil nails is an important consideration when selecting the right type of nail for your application. The point type can affect the penetration and holding power of the nail, as well as the appearance of the finished product.

Here are some factors to consider when choosing the right point type for your pallet coil nails:

Material: The material of the wood or other material being fastened can affect the point type you choose. For example, a diamond point is ideal for hard woods, while a blunt point may be better suited for softer woods.

Application: The application of the pallet coil nails can also influence the point type you choose. For example, a chisel point is ideal for fastening pallets and crates, while a diamond point may be better suited for framing.

Holding power: The point type can affect the holding power of the nail. A diamond point provides greater holding power than a blunt point, for example, while a chisel point provides a good balance between holding power and ease of penetration.

Appearance: The point type can also affect the appearance of the finished product. A blunt point leaves a smaller hole than a diamond point, for example, which can be important in applications where appearance is a consideration.

Overall, the right point type for your pallet coil nails will depend on the specific application and the materials being fastened. Consider the factors above when selecting the point type and be sure to follow the manufacturer's recommendations for the best results.

How does the point type affect the ease of penetration?

The point type of pallet coil nails can affect the ease of penetration, pallet coil nails which is the ability of the nail to penetrate the material being fastened without splitting or damaging it. Different point types are designed to penetrate different types of materials with varying levels of ease.

Here's how the point type affects the ease of penetration:

Blunt point: A blunt point has a flat end and is designed for use in softwood or other soft materials. It is less likely to split the wood than a sharp point, but it may require more force to penetrate the material.

Chisel point: A chisel point has a flattened end with a sharp edge and is designed for use in hardwood or other dense materials. The chisel shape helps to prevent splitting while still allowing for easy penetration.

Diamond point: A diamond point has a sharp point and is designed for use in hard and dense materials. The sharp point allows for easy penetration, but it may also be more likely to split the wood.

Blunt diamond point: A blunt diamond point has a flat end with a diamond-shaped point and is designed for use in medium-hard materials. It provides good penetration while minimizing the risk of splitting.

Overall, the point type of pallet coil nails can affect the ease of penetration depending on the specific application and the materials being fastened. It's important to choose the right point type for your application to ensure that the nail penetrates the material effectively without causing damage or splitting.