yolissa hair

@yplissahairyolissa hair

Updates

Info

Personal Information

- First Name yolissa

- Last Name hair

- Gender Female

- Birthday March 15, 1994

Contact Information

- Website http://www.limapoultrymach.com

- Twitter https://twitter.com/westkiss2

Personal Details

-

About Me

Lima Machinery has been in the business of manufacturing agricultural feed pellet making machines for 20 years. https://www.limapoultrymach.com/

Blogs

Posted July 4, 2021

More and more people have owned hair wigs. If you bought a real human hair wig, then you can get a real wig lo...

Posted July 1, 2021

Hd lace wigs are the most natural lace wigs and more popular. Most people are interested in HD la...

Forum Posts

-

Posted in the topic 200°C Polyimide Rectangular Aluminum Enamelled Wire in the forum News and AnnouncementsAugust 2, 2023 2:26 AM EDT

Introduction:

In the realm of electrical engineering, the demand for high-performance wiring solutions is ever-increasing. One such remarkable innovation that has garnered attention in recent years is the 200°C polyimide rectangular aluminum enamelled wire. This cutting-edge wire combines the superior thermal resistance of polyimide with the conductivity of aluminum, resulting in a versatile and efficient electrical conductor. In this blog, we will delve into the features, applications, and advantages of this remarkable wire.

Understanding 200°C Polyimide Rectangular Aluminum Enamelled Wire:

The 200°C polyimide rectangular aluminum enamelled wire is a type of magnet wire, also known as winding wire, that is primarily used in the construction of electrical motors, transformers, and various other electrical equipment. It is composed of a rectangular-shaped aluminum conductor, which provides excellent conductivity, and a polyimide enamel insulation that withstands temperatures up to 200°C.Features and Benefits:

High Temperature Resistance: One of the most notable features of the 200°C polyimide rectangular aluminum enamelled wire is its exceptional resistance to high temperatures. With a maximum operating temperature of 200°C, it can endure the demanding conditions typically encountered in electrical appliances, ensuring optimal performance and reliability.Excellent Thermal Conductivity: The aluminum conductor of this wire offers excellent thermal conductivity. This feature allows for efficient heat dissipation, which is particularly crucial in high-power electrical applications. The wire effectively minimizes the risk of overheating and helps maintain the longevity of electrical equipment.

Superior Electrical Conductivity: Aluminum is known for its excellent electrical conductivity. The rectangular shape of the conductor in this wire further enhances its conductivity, resulting in low resistive losses during the transmission of electrical current. This attribute translates into improved energy efficiency and reduced power consumption.

Lightweight and Space-Saving: Compared to other traditional copper-based wires, the aluminum conductor in this wire is significantly lighter, making it ideal for applications that require weight reduction. Moreover, the rectangular shape of the conductor allows for space-saving installation, enabling more compact designs of electrical equipment.

Applications:

The 200°C polyimide rectangular aluminum enamelled wire finds applications in various industries, including:Electrical Motors: It is widely used in the construction of high-performance motors, such as those used in industrial machinery, automotive applications, and appliances. The wire's ability to withstand high temperatures and its excellent electrical conductivity make it an ideal choice for motor windings.

Transformers: This wire is well-suited for transformer windings due to its high temperature resistance and exceptional electrical properties. Transformers that operate in demanding environments, such as power distribution networks, can benefit from the superior thermal stability and efficiency of this wire.

Electric Vehicles: As the demand for electric vehicles continues to rise, the need for efficient and reliable motor windings becomes crucial. The 200°C polyimide rectangular aluminum enamelled wire is finding applications in the construction of electric vehicle motors, where its high temperature resistance and lightweight properties are highly advantageous.

Aerospace and Defense: The wire's ability to withstand high temperatures, coupled with its lightweight construction, makes it suitable for aerospace and defense applications. It can be found in aerospace components, such as actuators, servos, and other critical electrical systems.

Conclusion:

The 200°C polyimide rectangular aluminum enamelled wire represents a remarkable advancement in the field of electrical engineering. Its ability to withstand high temperatures, excellent electrical and thermal conductivity, and lightweight design make it an ideal choice for various applications. As technology continues to evolve, this innovative wire opens up new possibilities for designing efficient, reliable, and compact electrical equipment across industries. -

Posted in the topic The Principal Advantage To Using Aluminum Coil in the forum Off-Topic DiscussionsJuly 5, 2023 3:52 AM EDT

Hello:

Aluminum coils are versatile and widely used in various industries, ranging from construction to packaging. They are made by rolling aluminum ingots into flat sheets, which are then coiled for convenient storage and transportation. One of the principal advantages of using aluminum coils is their unique combination of properties that make them ideal for a wide range of applications.Durability and Corrosion Resistance

One of the most significant benefits of using aluminum coils is their high level of durability and resistance to corrosion. Aluminum is naturally resistant to rust and oxidation, and when combined with coatings or treatments, can provide even greater protection against harsh environments. This makes it an excellent choice for outdoor applications, such as roofing, siding, and gutters, where it is exposed to the elements.

Lightweight and Strong

Aluminum is an incredibly lightweight material that is also incredibly strong. In fact, aluminum has a strength-to-weight ratio that is higher than steel, making it an ideal choice for applications that require both strength and portability. This makes aluminum coils an excellent choice for use in transportation, such as in the construction of aircraft, automobiles, and trains.Flexibility and Formability

Another significant advantage of using aluminum coils is their flexibility and formability. Aluminum is a highly malleable material, allowing it to be easily shaped and formed into complex shapes and structures. This makes it an ideal choice for use in applications such as packaging, where it can be easily formed into containers and other shapes.Low Maintenance and Cost-Effective

Aluminum coils are also incredibly low maintenance and cost-effective. They require little upkeep or maintenance and can last for many years without needing to be replaced. Additionally, aluminum is one of the most cost-effective materials available, making it an ideal choice for use in a wide range of applications.Environmentally Friendly

Finally, using aluminum coils is an environmentally friendly choice. Aluminum is 100% recyclable, which means that it can be melted down and reused indefinitely without losing its properties or quality. This makes it an ideal choice for use in sustainable and eco-friendly applications, such as in the construction of green buildings.In conclusion, aluminum coils offer a wide range of benefits that make them an ideal choice for use in various industries. They are durable, corrosion-resistant, lightweight, strong, flexible, formable, low maintenance, cost-effective, and environmentally friendly. With such a unique combination of properties, it is no wonder that aluminum coils are becoming an increasingly popular choice for many different applications.

You can also go to see the other enameled wires like enameled square copper wire, enameled round copper wire and enameled flat copper wire.

-

Posted in the topic Single Strand Enamel Continuously Transposed Conductor in the forum TechnologyJune 28, 2023 6:13 AM EDT

Polyvinylformal (PVF) is a type of enamel coating that is often used to insulate copper wire in electrical applications. PVF-coated wire is highly resistant to heat and abrasion, making it an ideal choice for a wide range of industrial and commercial applications. One of the most interesting applications of PVF-coated wire is in the form of Continuously Transposed Conductors (CTCs), which are used in high-efficiency electrical motors and generators.

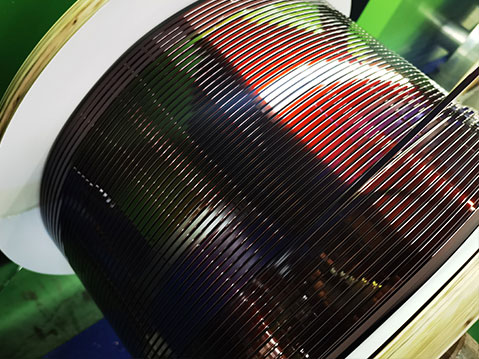

CTCs are essentially a series of thin copper wires that are coated with enamel and then continuously transposed, or twisted, to create a single strand. This strand is then wound into a coil, which is used to create the stator or rotor in an electrical motor or generator. By continuously transposing the wires, the current flowing through the conductor is evenly distributed, which reduces the risk of hot spots and other forms of electrical stress that can lead to premature failure.

One of the key advantages of PVF-coated CTCs is their ability to withstand high temperatures. PVF has a melting point of around 120°C, which means that CTCs made from this material can operate in environments that would be too hot for other types of wire. This makes them ideal for use in applications such as electric cars, where the motor may reach temperatures of up to 200°C during operation.

Another advantage of PVF-coated CTCs is their high electrical efficiency. Because the wires are continuously transposed, the current flows through the conductor more evenly, which reduces resistance and minimizes energy loss. This makes them ideal for use in high-efficiency motors and generators, where every percentage point of efficiency can make a significant difference in overall performance.

Overall, PVF-coated CTCs are an excellent choice for a wide range of electrical applications. Their high temperature resistance, excellent electrical efficiency, and ability to withstand abrasion and other forms of physical stress make them ideal for use in electric cars, industrial equipment, and other demanding environments. If you're looking for a high-performance wire solution for your next project, consider using PVF-coated CTCs.

-

Posted in the topic Enameled Wires Application Area in the forum TechnologyJune 8, 2023 4:32 AM EDT

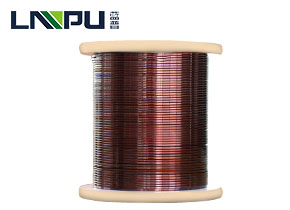

Enameled wires, also known as magnet wires, are copper or aluminum wires coated with a thin layer of enamel insulation. The enamel insulation provides electrical insulation and prevents short-circuiting when the wire is wound into coils. Enameled wires have a wide range of applications, including in the electrical and electronics industry. In this blog post, we will explore the various application areas of enameled wires.

Motors and Transformers:

Enameled wires are extensively used in the manufacturing of motors and transformers. They are used to make the coils in the stator and rotor of an electric motor. The coils are then connected to form a magnetic field that rotates the motor's shaft. Similarly, enameled wires are used in transformers to make the primary and secondary coils. The primary coil is connected to the input voltage, and the secondary coil is connected to the output voltage. The enamel insulation prevents the coils from short-circuiting and enhances the transformer's efficiency.Electrical and Electronic Devices:

Enameled wires are used in various electrical and electronic devices, including generators, sensors, relays, solenoids, and switches. In generators, enameled wires are used to make the coils that produce the electrical energy. In sensors, enameled wires are used to detect changes in temperature, pressure, and other parameters. In relays, enameled wires are used to switch on or off the electrical circuits. In solenoids, enameled wires are used to make the magnetic field that pulls or pushes a plunger. In switches, enameled wires are used to make the contacts that connect or disconnect the electrical circuits.Automotive Industry:

Enameled wires are used in the automotive industry for various applications, including in ignition coils, starters, and alternators. In ignition coils, enameled wires are used to make the primary and secondary coils that produce the spark. In starters, enameled wires are used to make the coils that rotate the engine. In alternators, enameled wires are used to make the stator and rotor coils that produce the electrical energy.Aerospace and Defense Industry:

Enameled wires are used in the aerospace and defense industry for various applications, including in communication systems, radar systems, and avionics. In communication systems, enameled wires are used to make the coils in the antennas that transmit and receive signals. In radar systems, enameled wires are used to make the coils that generate the electromagnetic waves. In avionics, enameled wires are used to make the coils in the sensors and actuators that control the aircraft's systems.Household Appliances:

Enameled wires are used in various household appliances, including in refrigerators, air conditioners, washing machines, and vacuum cleaners. In refrigerators and air conditioners, enameled wires are used to make the coils that produce the cooling effect. In washing machines, enameled wires are used to make the coils that rotate the drum. In vacuum cleaners, enameled wires are used to make the coils in the motor that generates the suction power.In conclusion, enameled wires have a wide range of applications in the electrical and electronics industry, automotive industry, aerospace and defense industry, and household appliances. The enamel insulation provides electrical insulation and prevents short-circuiting, making enameled wires a crucial component in many devices and systems.

-

Posted in the topic What is special about magnet wire? in the forum SuggestionsMay 19, 2023 2:50 AM EDT

Magnet wire, also known as winding wire, is a type of wire used in the construction of electrical devices such as transformers, motors, and generators. It is made from copper or aluminum and is coated with a thin layer of insulation, typically enamel, to prevent short circuits and ensure proper electrical performance. Magnet wire is an essential component in the functioning of many electrical devices, and its unique properties make it a critical material for electrical engineering.

So, what makes magnet wire so special? In this blog post, we'll explore the characteristics of magnet wire that make it an indispensable material in the field of electrical engineering.

High conductivity

One of the primary properties that makes magnet wire special is its high conductivity. Copper, which is the most commonly used material for magnet wire, is an excellent conductor of electricity. This means that electrical energy can flow easily through the wire, with minimal resistance or loss of power.

High conductivity is critical for the functioning of many electrical devices, including motors and transformers, as it enables the efficient transfer of electrical energy. This, in turn, results in improved performance and reduced energy waste.

Thin insulation

Another unique property of magnet wire is its thin insulation layer. Unlike other types of wire that have thicker insulation, magnet wire has a very thin layer of enamel coating. This allows for more wire to be wound in a given space, making it ideal for use in small electrical devices such as computer hard drives and speakers.

Thin insulation also improves the electrical properties of the wire by reducing the capacitance and increasing the inductance. This, in turn, helps to minimize signal distortion and improve overall electrical performance.

Heat resistance

Magnet wire is designed to withstand high temperatures without degrading or losing its electrical properties. This is essential for devices that generate a lot of heat, such as transformers and motors.

The high temperature resistance of magnet wire is due to the enamel coating, which is made from materials such as polyurethane, polyester, and nylon. These materials are specifically chosen for their ability to withstand high temperatures without melting or degrading.

Flexibility

Magnet wire is also very flexible, which makes it easy to wind and shape into the desired form. This is particularly important for devices such as motors and transformers, where the wire must be wound around a core or coil.

The flexibility of magnet wire is due to the thin insulation layer, which allows the wire to be bent and shaped without breaking or damaging the insulation. This, in turn, makes it easier to construct complex electrical devices with precise dimensions.

In conclusion, magnet wire is a unique and essential material in the field of electrical engineering. Its high conductivity, thin insulation, heat resistance, and flexibility make it an ideal choice for many different applications, from small electrical devices to large transformers and motors. Without magnet wire, many of the electrical devices we rely on today would not be possible, making it truly special.